Complete Buying Guide: FRANCIS TURBINE

The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today, and can achieve over 95% efficiency.[1]

The process of arriving at the modern Francis runner design took from 1848 to approximately 1920.[1] It became known as the Francis turbine around 1920, being named after British-American engineer James B. Francis who in 1848 created a new turbine design.[1]

Francis turbines are primarily used for producing electricity. The power output of the electric generators generally ranges from just a few kilowatts up to 1000 MW, though mini-hydro installations may be lower. The best performance is seen when the head height is between 100–300 metres (330–980 ft).[2] Penstock diameters are between 1 and 10 m (3.3 and 32.8 ft). The speeds of different turbine units range from 70 to 1000 rpm. A wicket gate around the outside of the turbine’s rotating runner controls the rate of water flow through the turbine for different power production rates. Francis turbines are usually mounted with a vertical shaft, to isolate water from the generator. This also facilitates installation and maintenance.

A Francis turbine consists of the following main parts:

Spiral casing: The spiral casing around the runner of the turbine is known as the volute casing or scroll case. Throughout its length, it has numerous openings at regular intervals to allow the working fluid to impinge on the blades of the runner. These openings convert the pressure energy of the fluid into kinetic energy just before the fluid impinges on the blades. This maintains a constant velocity despite the fact that numerous openings have been provided for the fluid to enter the blades, as the cross-sectional area of this casing decreases uniformly along the circumference.

Guide and stay vanes: The primary function of the guide and stay vanes is to convert the pressure energy of the fluid into kinetic energy. It also serves to direct the flow at design angles to the runner blades.

Draft tube: The draft tube is a conduit that connects the runner exit to the tail race where the water is discharged from the turbine. Its primary function is to reduce the velocity of discharged water to minimize the loss of kinetic energy at the outlet. This permits the turbine to be set above the tail water without an appreciable drop of the available head.

The Francis turbine is a type of reaction turbine, a category of the turbine in which the working fluid comes to the turbine under immense pressure and the energy is extracted by the turbine blades from the working fluid. A part of the energy is given up by the fluid because of pressure changes occurring on the blades of the turbine, quantified by the expression of the degree of reaction, while the remaining part of the energy is extracted by the volute casing of the turbine. At the exit, water acts on the spinning cup-shaped runner features, leaving at low velocity and low swirl with very little kinetic or potential energy left. The turbine’s exit tube is shaped to help decelerate the water flow and recover the pressure.

Suneco Francis Turbine Generators Advantages

1. Comprehensive processing capacity. Such as 5M CNC VTL OPERATOR, 130 & 150 CNC floor boring machines, constant temperature annealing furnace, planer milling machine, CNC machining center, etc.

2. Designed lifespan is more than 40 years.

3. Suneco provides a one-time free site service if the customer purchases three units (capacity ≥100kw) within one year, or the total amount is more than 5 units. Site service included equipment inspection, new site checking, installation, maintenance training, etc,

4. OEM accepted.

5. CNC machining, dynamic balance tested and isothermal annealing processed, NDT test.

6. Design and R&D Capabilities,13 senior engineers with experience in design and research.

7. The technical consultant worked in the hydro turbine field for 50 years and was awarded the Chinese State Council Special Allowance.

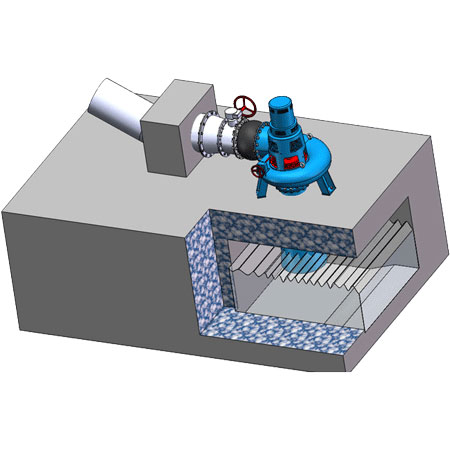

Francis turbine is applicable to middle and low water head and middle and small flow of hydropower station. The micro hydropower project is usually using vertical type Francis turbine generator systems. The turbine is mainly composed of a spiral case (water diversion chamber), turbine runner or wheel, water guide vane (wicket gates), draft tube, etc.

Francis turbine is a kind of turbine suited to water heads 20-300 meters and with a certain suitable flow.

It could be divided into vertical and horizontal arrangements. Francis turbines have the advantage of high efficiency, small size, and reliable structure.

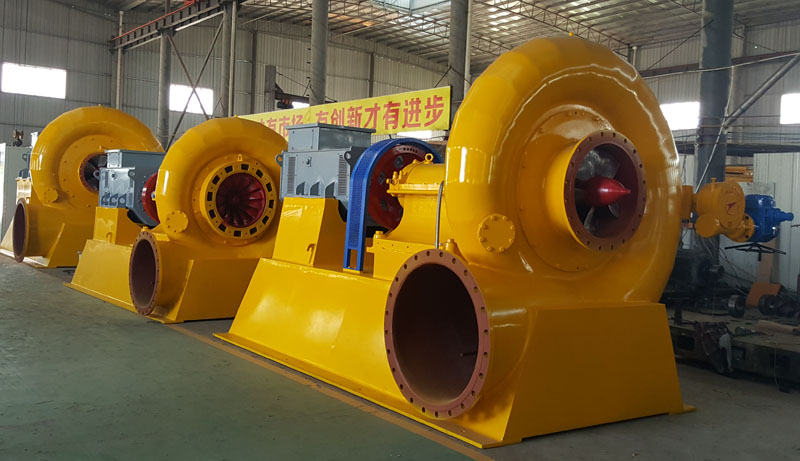

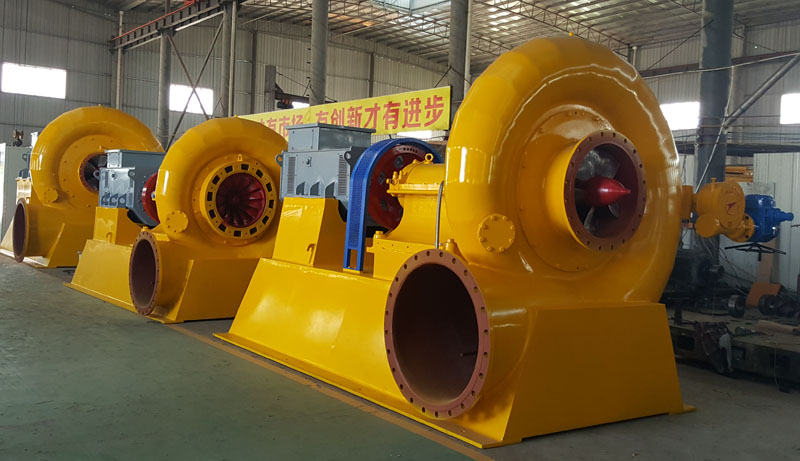

A horizontal Francis turbine unit, with a horizontal shaft, could be 2 or three supports. Which is normally one stair arrangement. Simple structure, easier operation, and maintenance.

Francis Turbine Generator China Factory: A Professional Overview

At our Francis turbine generator factory in China, we pride ourselves on producing high-quality and efficient turbines that meet the needs of our clients. Our factory is equipped with state-of-the-art technology and machinery, allowing us to manufacture turbines that are reliable and long-lasting.

Our team of experienced engineers and technicians work tirelessly to ensure that every turbine that leaves our factory meets our strict quality standards. We use only the best materials and components to ensure that our turbines are not only efficient, but also durable and able to withstand the demands of heavy use.

When you choose a Francis turbine generator from our factory in China, you can be confident that you are getting a product that is designed and manufactured to the highest standards. Whether you need a turbine for a hydroelectric power plant or for other industrial applications, we have the expertise and experience to deliver a product that meets your needs.

Overview of Francis Turbine Generators

At our China factory, we specialize in manufacturing Francis turbine generators. These generators are widely used in hydroelectric power plants and are known for their high efficiency and reliability.

A Francis turbine generator is a type of water turbine that converts the energy from moving water into electrical energy. It consists of a turbine wheel, a runner, and a generator. The turbine wheel is driven by the force of the water, which causes the runner to rotate. The generator is then used to convert the mechanical energy from the runner into electrical energy.

Our Francis turbine generators are designed to meet the specific needs of our clients. We offer a range of models with different power outputs, ranging from a few kilowatts to several megawatts. Our generators are also designed to operate at various water pressures and flow rates, making them suitable for a wide range of hydroelectric power plants.

In addition to their high efficiency and reliability, our Francis turbine generators are also designed to be easy to install and maintain. We use high-quality materials and advanced manufacturing techniques to ensure that our generators are built to last.

Overall, our Francis turbine generators are an excellent choice for hydroelectric power plants looking for a reliable and efficient source of electricity. With our years of experience and expertise, we are confident that we can provide our clients with the best possible solutions for their power generation needs.

China’s Role in Francis Turbine Generator Production

China has become a major player in the production of Francis turbine generators. Our research shows that China is now the largest producer of Francis turbine generators in the world. We have identified several factors that have contributed to China’s success in this area.

Firstly, China has invested heavily in the development of its manufacturing sector. This has allowed Chinese companies to produce high-quality products at a lower cost than their competitors. In addition, the Chinese government has provided support to the industry through subsidies and other incentives.

Secondly, China has a large pool of skilled workers. The country has a strong education system and produces a large number of graduates in engineering and other technical fields. This has allowed Chinese companies to develop and manufacture complex machinery such as Francis turbine generators.

Thirdly, China has a large domestic market for Francis turbine generators. The country is rapidly developing its infrastructure, which requires large amounts of electricity. This has created a strong demand for Francis turbine generators, which Chinese companies have been able to meet.

Finally, Chinese companies have been able to expand their reach beyond the domestic market. They have been successful in exporting Francis turbine generators to other countries, particularly in Asia and Africa. This has helped to further increase China’s share of the global market.

In conclusion, China’s success in Francis turbine generator production can be attributed to a combination of factors, including government support, a skilled workforce, a large domestic market, and successful exports. As a result, China has become a major player in this industry and is likely to continue to grow in importance in the years to come.

Key Francis Turbine Generator Factories in China

When it comes to Francis turbine generators, China is one of the leading countries that manufacture and export these products. We have researched and identified some of the key factories in China that produce Francis turbine generators.

Factory 1: Suneco Hydro

Suneco hydro specializes in the manufacturing of power generation equipment. They have a wide range of products, including Francis turbine generators, which are used in hydroelectric power plants.

Factory 2: Harbin Electric Corporation

Harbin Electric Corporation is another leading manufacturer of Francis turbine generators in China. The company was established in 1951 and is headquartered in Harbin, China. They have a strong presence in the power generation industry and have supplied equipment to many countries around the world.

Factory 3: Shanghai Electric Group

Shanghai Electric Group is a multinational power generation equipment manufacturer that produces Francis turbine generators. The company was founded in 2004 and is headquartered in Shanghai, China. They have a wide range of products, including wind turbines, gas turbines, and hydro turbines.

These are just a few of the key Francis turbine generator factories in China. There are many other manufacturers in China who produce high-quality products. As a professional in the power generation industry, we recommend these factories as reliable sources for Francis turbine generators.

Manufacturing Processes of Francis Turbine Generators

At our China factory, we follow a strict manufacturing process to ensure the highest quality Francis turbine generators for our customers. Our manufacturing process includes the following steps:

Step 1: Casting

We start by casting the turbine runner, guide vanes, and other components using high-quality stainless steel. The casting process is done using precision molds to ensure the exact shape and size of each component.

Step 2: Machining

After casting, we move on to machining the components to their final shape and size. This step involves using CNC machines to achieve precise tolerances and a smooth finish.

Step 3: Assembly

Once the machining is complete, we assemble the components together to form the Francis turbine generator. This step involves fitting the turbine runner onto the shaft, attaching the guide vanes, and installing the bearings and other components.

Step 4: Testing

Before shipping the Francis turbine generator to our customers, we perform rigorous testing to ensure it meets all performance specifications. This includes testing for efficiency, power output, and other critical parameters.

Overall, our manufacturing process ensures that our Francis turbine generators are of the highest quality and reliability. We take pride in our work and strive to provide the best possible products to our customers.

Quality Control in Chinese Francis Turbine Generator Factories

At our Francis turbine generator factory in China, we take great pride in our commitment to quality control. We understand that our customers rely on our products to provide reliable and efficient power generation, and we take that responsibility very seriously.

To ensure the highest level of quality, we have implemented a rigorous quality control process that includes multiple checks and inspections throughout the manufacturing process. Our quality control team is made up of experienced engineers and technicians who are dedicated to ensuring that every component meets our strict standards.

One of the key components of our quality control process is our use of advanced testing equipment. We utilize a variety of tools and technologies to test each component, including ultrasonic testing, X-ray testing, and magnetic particle testing. These tests allow us to identify any potential defects or flaws in the materials or components, so that we can address them before they become a problem.

In addition to our testing equipment, we also have a comprehensive documentation system in place. Every component is carefully tracked and documented throughout the manufacturing process, from the initial design phase to final assembly. This allows us to quickly identify any issues that may arise, and to take corrective action as needed.

Overall, our commitment to quality control is a key factor in our success as a Francis turbine generator factory in China. We believe that by maintaining the highest level of quality in our products, we can continue to build strong relationships with our customers and provide them with the reliable power generation solutions they need.

Export and Import Policies

At our Francis turbine generator factory in China, we are committed to complying with all relevant export and import policies. Our team is dedicated to ensuring that our products meet all necessary regulations and standards, and that they are shipped safely and efficiently to our customers around the world.

When it comes to exporting our Francis turbine generators, we work closely with our shipping partners to ensure that all necessary documentation and permits are in place. We provide detailed information about our products, including technical specifications, shipping dimensions, and weight, to help our customers plan and prepare for the arrival of their order.

In terms of import policies, we are constantly monitoring changes and updates to regulations in different countries to ensure that we are in compliance with all requirements. We work with our customers to provide any necessary documentation or certificates to facilitate the import process, and we strive to make the process as smooth and hassle-free as possible.

We understand that navigating export and import policies can be a complex and challenging process, but our team is here to help. We are committed to providing our customers with the highest level of service and support, and we will do everything we can to ensure that their experience with us is positive and successful.

Future Trends of Francis Turbine Generators in China

Technological Advancements

We anticipate that the future of Francis turbine generators in China will be marked by significant technological advancements. With the increasing demand for clean energy, there is a growing need for more efficient and reliable turbines. Manufacturers are investing heavily in research and development to improve the efficiency and performance of Francis turbines.

One area of focus for technological advancements is in the materials used to manufacture the turbines. We expect to see an increase in the use of high-strength materials, such as composites, to improve the durability and reliability of the turbines. Additionally, advancements in digital control systems and sensors will enable more precise control of the turbines, resulting in improved efficiency.

Market Trends

As the demand for clean energy continues to grow, we expect to see a significant increase in the adoption of Francis turbine generators in China. The government’s commitment to reducing carbon emissions and increasing the share of renewable energy in the country’s energy mix is expected to drive the growth of the market.

In addition, the growing demand for hydropower in other countries in the region, such as India and Southeast Asia, presents an opportunity for Chinese manufacturers to expand their market share. We anticipate that Chinese manufacturers will continue to dominate the global market for Francis turbine generators, given their competitive pricing and high-quality products.

To summarize, we believe that the future of Francis turbine generators in China is bright, with significant technological advancements and a growing market demand for clean energy. Manufacturers are investing heavily in research and development to improve the efficiency and performance of the turbines, while the government’s commitment to reducing carbon emissions is expected to drive the growth of the market.