Description

Short Description:

GLYWT series Programmable Microcomputer Hydro-governor (PMH) is applied in medium and small-sized water-turbine electricity generator sets.

It is united cabinet of controller, mechanic and hydraulic system. High stability Programmable Logic Controller (PLC) is the controller.

High oil pressure devices, digital and standardization design are adopted in mechanical part. It takes high quality standardized digital hydraulic valves as actuators, easy for replacement and system update.

Such simplifies system structure of PMH, avoids complication and low stabilization of traditional Hydro-governor.

AC power supply: ~220V±10%,50HZ

DC power supply: 220V±10%

Work oil pressure: 12~17Mpa

Switching power supply voltage:+24V

Guide vane position feedback voltage :0 ~ 10V

The guide vane opening of 0 ~ 100% corresponds to (0 ~ 10)V

Resistance: 5 Κ Ω plus or minus 20%,

Accuracy: + / – 0.05%

Technical Data

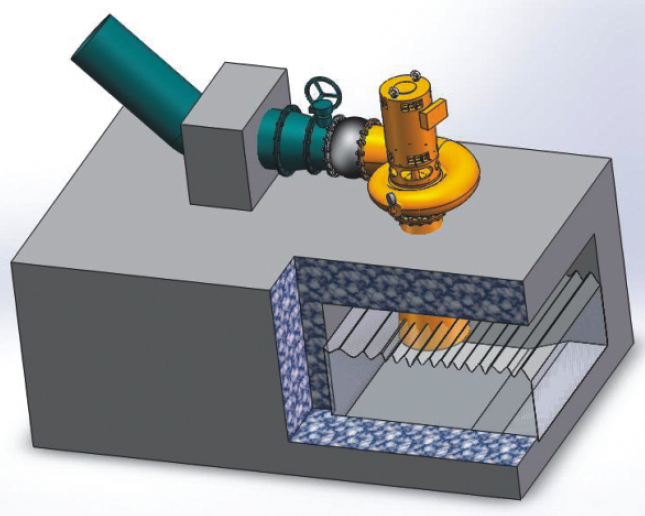

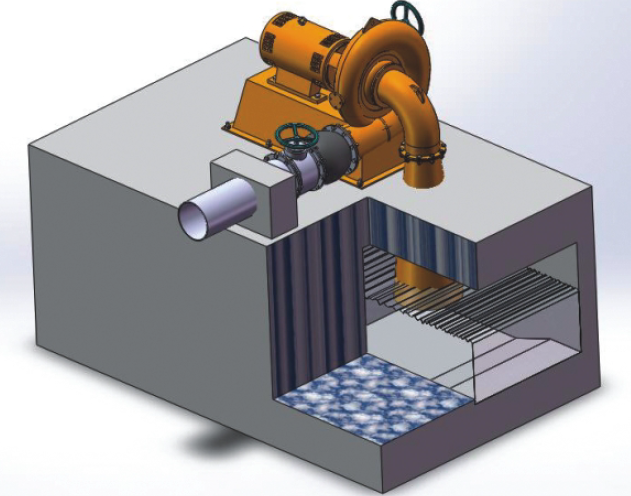

Microcomputer governor is composed of electric control system and hydraulic system.

Microcomputer governor adopts PLC as the central regulator .

PLC is the use of high-performance Japanese mitsubishi FX series as the main hardware. It uses the touch graphic operation terminal as the man-machine interface, and coordinates with the suitable mechanical and hydraulic servo system to realize the speed adjustment and output control of the hydro-generator set.

The electric control system is installed in the electric control cabinet, which is fixed above the hydraulic system.This design realizes the separation of the hydraulic and electrical, without oil stain pollution.

There are doors on the front and back of the cabinet, and dustproof seal and lock is installed on the door, which is convenient for mechanical and electrical installation, maintenance and repair.The bottom of the cabinet is equipped with cable duct inlet and outlet for easy installation and debugging.Cabinet appearance is neat and beautiful, and has enough stiffness and strong foundation mechanism, not because of hydraulic and high-speed oil flow caused by vibration.

The power supply part of the electronic control system adopts ac - dc dual power supply, which can be used as backup for each other. It can switch automatically without disturbance, and its reliability is greatly enhanced.

Microcomputer governor with the hydraulic circuit, can achieve manual, automatic pressure. It comes with motor overload and lack of phase protection, protection of oil pump motor.

More Details

Hydraulic system adopts oil control mode to control the displacement of the servomotor. During normal operation, the microcomputer selects different hydraulic circuits for control according to the specific control quantity.

Hydraulic device adopts high pressure gear pump and accumulator, making the design simple, compact, beautiful appearance, good sealing performance, no leakage, safe and reliable, fast response, low fuel consumption (energy saving), long life and other characteristics.